Project Engineer

Job Description

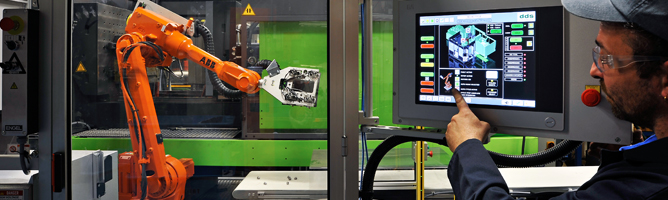

Located in Bristol, Rhode Island for nearly 50 years, Tri-Mack is a leading manufacturer of high-temperature thermoplastic components for the aerospace-defense, semiconductor, energy and medical industries.

Our broad capabilities include collaborative engineering, tool making, injection molding, thermoplastic composite processing, multi-axis CNC machining, bonding and assembly, testing and quality control - all within a modern, environmentally controlled 60,000 sq. ft. facility.

Our culture is based on values that promote respect, teamwork and accountability and we are committed to meeting customer requirements through our ISO 9001/AS9100 quality management system.

PLEASE NOTE - Applicants must be authorized to work for any employer in the U.S. We are unable to sponsor or take over sponsorship of an employment visa at this time.

Position: Project Engineer

Summary:

The Project Engineer manages several concurrent active engineering projects, which may involve New Product Introduction (NPI), changes to current products and/or process improvements, working with a cross-functional team and responsible for ensuring on time, on-budget completion.

Responsibilities & Accountabilities:

- Analyze equipment, systems, and processes to Identify and initiate projects to improve productivity improve efficiency, increase quality, decrease waste and reduce costs.

- Participate as a team member with Marketing, Quality Control, Production, Customers and Vendors to accomplish on time and on-budget projects to completion.

- Manage New Product Introduction projects using the established NPI Tollgate process.

- Work closely with internal and external customers to ensure that part designs are manufacturable, cost effective and can meet high quality standards.

- Design new processes, parts, fixtures and tools using SolidWorks, Cimatron and Moldflow as well as improvements to existing parts.

- Prepare Engineering masters, including any IPQC detail as needed for any new parts under the NPI umbrella as well as update masters when process improvements are involved.

- Utilize Lean and Six Sigma tools to reduce waste and implement robust part and process designs.

- Support Production in identifying root cause, and corrective action implementation of ongoing issues.

- Work closely with Quality Control to ensure all parts meet specified drawing requirements.

- Adhere to all ISO 9001 and AS9100 requirements.

- Conduct yourself in an ethical and professional manner and always follow Tri-Mack Values: Respect, Teamwork, Integrity, Accountability and Durability

- Assist with special projects and other duties as assigned.

Skills & Experience

- Associates in Engineering, Bachelors in Engineering preferred

- Experience in a manufacturing environment with some of these processes preferred:

- Injection molding, CNC Milling, CNC Turning, Composite Manufacturing, Assembly, Bonding

- Experience with CAD design, SolidWorks preferred; Proficient with Microsoft Office Suite

- Demonstrated blueprint interpretation, GD&T experience preferred

- Some experience with Lean and/or Six-Sigma preferred

- Strong written and oral communication skills.

- Excellent organizational skills and attention to detail, analytical and problem-solving skills.

- Time management skills with a proven ability to meet deadlines.

- Flexible, work with a high sense of urgency, and able to get along well with others.

Our Benefits:

We offer competitive salaries and generous benefits, including:

- 9 day / 80 hour (M-F+M-TH) or 5 day / 40 (M-F) hour schedule

- Medical, Life & Dental Insurance

- Paid Holiday, Personal Time & Vacation

- 401(k) with Company Match

- Tuition Reimbursement

If you are looking for an innovative, values-driven company where you can put your engineering aptitude and expertise to work, grow your career and take on ever-bigger challenges, you may just have found the place! We know our continued success is dependent upon our employees, which is why we are always on the lookout for reliable, knowledgeable and dynamic individuals with past success in a collaborative team setting, working with clear objectives and direction.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening (excludes THC) and background checks are required.