Materials expertise delivers high performance.

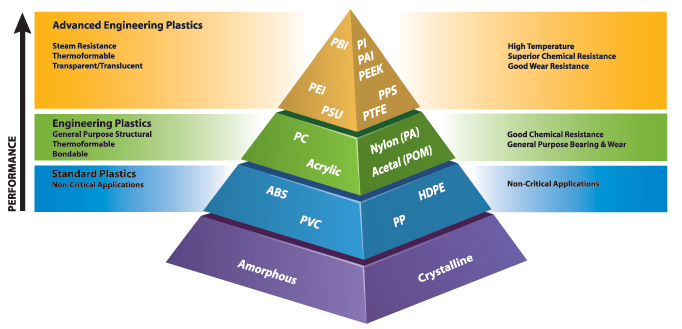

Our solutions start with intimate materials knowledge. Tri-Mack is focused on the highest performance engineering thermoplastics and thermoplastic composites. Whether you’re looking for increased strength or improved wear resistance, we have the expertise to make it happen.

Tri-Mack uses many different standard and custom compounds to meet your application’s goals, from self-lubricated plastic bushings to light weight aerospace structural components. These compounds include carbon fiber, glass fiber and PTFE fillers and come to us in many forms from injection mold pellets to extruded shapes to unidirectional tape. Our team works with materials from all the major suppliers, ensuring the best material is used for each application.

- Polyimides (PI) - Vespel, Meldin, Aurum

- Polybenzimidazole (PBI) - Celazole

- Polyamide-imide (PAI) - Torlon

- Polyetheretherketone (PEEK) - Victrex, Ketaspire

- Liquid Crystal Polymer (LCP) - Vectra, Xydar

- Polyetherimide (PEI) - Ultem

- Polysulfone - Radel, Udel

- Polyphenylene Sulfide (PPS) - Fortron, Ryton, Supec

- Polyphthalamide (PPA) - Amodel

- Polytetrafluoroethylene (PTFE) - Teflon, Hostaflon

- Aromatic Polyamids - Zytel, High Temperature Nylon

- Others - Delrin, Valox, PC, and more

- Metals - Aluminum, Titanium, Stainless Steel, Bronze