CNC Machinist - Set Up Technician (2nd Shift)

Job Description

Located in Bristol, Rhode Island for nearly 50 years, Tri-Mack is a leading manufacturer of high-temperature thermoplastic components for the aerospace-defense, semiconductor, energy and medical industries.

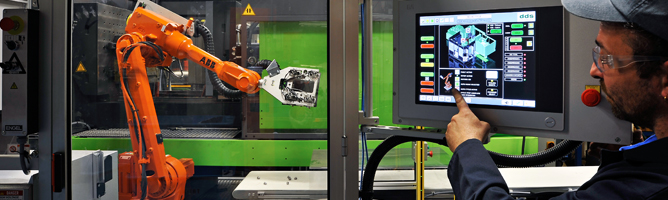

Our broad capabilities include collaborative engineering, tool making, injection molding, thermoplastic composite processing, multi-axis CNC machining, bonding and assembly, testing and quality control - all within a modern, environmentally controlled 60,000 sq. ft. facility.

Our culture is based on values that promote respect, teamwork and accountability and we are committed to meeting customer requirements through our ISO 9001/AS9100 quality management system.

PLEASE NOTE - Applicants must be authorized to work for any employer in the U.S. We are unable to sponsor or take over sponsorship of an employment Visa at this time.

Position: CNC Machinist Level 3 / Set-Up Technician (2nd shift)

Summary:

This position uses Tri-Mack's CNC and manual machining equipment to set up tight tolerance parts using pre-defined programs, tools, and work holding. This position can independently set up the majority of jobs across most machine platforms within the CNC department. The CNC Set-up Technician is responsible for troubleshooting issues that come up during a production run, and supports teammates with tool changes and offsets as needed. The CNC Set-up Technician may provide some program modifications and offer actionable improvements to production processes.

Responsibilities & Accountabilities:

- Consistently set-up and operate multiple CNC machines to specifications and hold tight tolerances for all parts within the department.

- Train coworkers on operating the CNC machines parts including the measurement techniques for all parts in the department.

- Identify correct loading technique from set-up files to ensure part conformance. Teach loading technique to operators at hand-off. Identify critical dimensions to be monitored more closely by operators.

- Change all tools and inserts and verify part conformance. Advise teammates about anticipated wear rates of jobs as part of the set up process.

- Perform all offsets, taper line adjustments and work offsets required to make consistently conforming parts. Identify key machining steps and manipulate machine to verify set up accuracy. Examples include: stopping/restarting a program before a part transfer, stopping/restarting a program to verify a roughing pass, and stopping/restarting a program after machining a single part in a gang-style programing process.

- Complete all documentation accurately each shift.

- Troubleshoot problems as they arise on the floor. .

- Verify raw material documentation and match picklists to maintain lot traceability.

- Independently perform all Preventative Maintenance tasks within the department and document per the relevant work instruction

- Keep work station clean and organized.

- Work in a manner that ensures your own safety and the safety of your co-workers. Always use correct PPE, and never run a machine without proper guarding.

- Conduct yourself in an ethical and professional manner and always follow Tri-Mack values: Respect, Teamwork, Integrity, Accountability and Durability

- Adhere to all AS9100 requirements as specified in work instructions and by your supervisor.

- All other duties assigned.

Skills & Experience

- High School diploma or general education degree (GED).

- Minimum of 5 years of experience on CNC milling and/or lathes machines is required.

- Experience in set-up and/or program edits is required.

- Solid understanding of blueprints and specifically GD&T is required.

- Physical ability to stand, bend, sit and lift up to 40 pounds for 8 to 12 hours per day.

- General math knowledge and ability to calculate and solve certain geometric problems.

- Ability to use and understand all measuring tools.

- Basic computer skills.

- Reliable, able to get along with co-workers and support others as needed

Our Benefits:

We offer competitive salaries and generous benefits, including:

- 40 hour week, Monday-Friday

- $3.00 / hour 2nd shift pay differential

- Medical, Life & Dental Insurance

- Paid Holiday, Personal Time & Vacation

- 401(k) with Company Match

- Tuition Reimbursement

If you’re looking for an innovative, values-driven company where you can put your mechanical aptitude and expertise to work, grow your career and take on ever-bigger challenges, you may just have found the place! We know our continued success is dependent upon our employees, which is why we are always on the lookout for reliable, knowledgeable and dynamic individuals with past success in a collaborative team setting, working with clear objectives and direction.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening (excludes THC) and background checks are required.