Toolmaker / Moldmaker

Job Description

Located in Bristol, Rhode Island for nearly 50 years, Tri-Mack is a leading manufacturer of high-temperature thermoplastic components for the aerospace-defense, semiconductor, energy and medical industries.

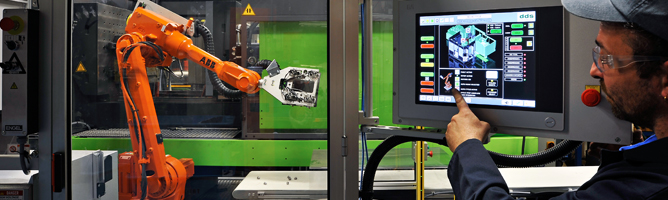

Our broad capabilities include collaborative engineering, tool making, injection molding, thermoplastic composite processing, multi-axis CNC machining, bonding and assembly, testing and quality control - all within a modern, environmentally controlled 60,000 sq. ft. facility.

Our culture is based on values that promote respect, teamwork and accountability and we are committed to meeting customer requirements through our ISO 9001/AS9100 quality management system.

PLEASE NOTE - Applicants must be authorized to work for any employer in the U.S. We are unable to sponsor or take over sponsorship of an employment visa at this time.

Position: Tool Maker / Mold Maker

Summary:

This position is responsible for operating all CNC and manual equipment located in our Tool Room. Work assignments may include reading and understanding blueprints, tool making, touch off of tools, layout, set up, minor machine maintenance, tool preparation and machine operation. The position requires direct communication with engineers and production in order to resolve issues. It also requires the ability to work independently, adhere to strict safety guidelines, maintain a clean work area and keep all equipment in good, working condition.

Responsibilities & Accountabilities:

- Perform all required machine operations located in the Tool Room (milling, grinding, turning, conventional and wire EDM) to construct, alter or repair injection molds, jigs, fixtures, dies and gauges.

- Operate CNC milling machines in the Tool Room as required.

- Assist in tool maintenance and preparation as required.

- Show up to work on time and adhere to the 40 hour schedule agreed upon by you and your supervisor. Get along with co-workers and support others as needed.

- Keep work station clean and organized. Work in a manner that ensures your own safety and the safety of your coworkers. Always use correct PPE and never run a machine without proper guarding. Maintain safe operations by adhering to safety procedures and regulations.

- Conduct yourself in an ethical and professional manner, show respect for your fellow workers and all company and personal property, and always follow Tri-Mack values - Respect, Teamwork, Integrity, Accountability, and Durability.

- Adhere to as per work instructions and your team leader and manager.

- Support and adhere to all ISO 9001 and AS9100 requirements as described by the Tri-Mack Plastics Quality Manual and supporting documentation.

- Pursue opportunities to develop new skills both within the department and across departmental lines.

- All other duties as assigned.

Skills & Experience

- Minimum of 5 years of related experience with tooling and machinery

- High School diploma or general education degree (GED).

- Strong mechanical aptitude is required; comfortable with hand tools.

- Working knowledge of standard OSHA regulations.

- Strong problem-solving and troubleshooting capability.

- Physical ability to properly move molds and other equipment as needed; to stand, bend, sit and lift up to 40 pounds for 8 to 12 hours per day.

- General math knowledge and ability to calculate and solve certain geometric problems.

- Ability to use and understand all measuring tools; Basic computer skills.

Our Benefits: We offer competitive salaries and generous benefits, including:

- 40 hour week, Monday-Friday, OT available

- Medical, Life & Dental Insurance

- Paid Holiday, Personal Time & Vacation

- 401(k) with Company Match

- Tuition Reimbursement

If you’re looking for an innovative, values-driven company where you can put your mechanical aptitude and expertise to work, grow your career and take on ever-bigger challenges, you may just have found the place! We know our continued success is dependent upon our employees, which is why we are always on the lookout for reliable, knowledgeable and dynamic individuals with past success in a collaborative team setting, working with clear objectives and direction.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening (excludes THC) and background checks are required.