Tooling Program Manager

Job Description

Tooling Program Manager

Position Summary: The Tooling Program Manager is responsible for managing the design, costing and build of plastic injection molds in-house or through outside sources. The Tooling Program Manager will create timelines to address customer expectations, supplier demands and in-house resources to ensure all new tooling is delivered on-budget and on-time. In addition, this position is the expert on technical issues and recommends new processes and procedures based on new technology to improve efficiencies. Finally, the Tooling Program Manager will work and communicate across company lines to address any tool room issues or delays.

Responsibilities & Accountabilities:

• Design, review, coordinate and advise on all new and existing tooling programs.

• Manage the preparation of quotes. Calculate cost and lead time to build new tools.

• Prepare Tooling Program schedules and utilize Visual to ensure work orders are entered and completed.

• Work with Engineers and Production to provide technical advice and support on all aspects of tool design, manufacturing and cost.

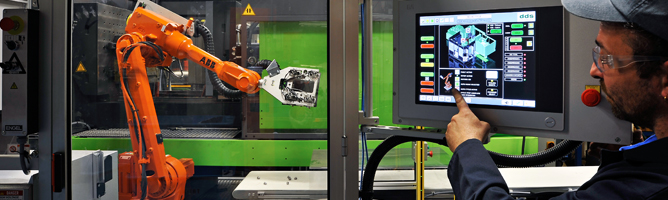

• Identify improvement opportunities within the Tool Room and recommend plans for new equipment and technology.

• Manage New Product Initiative (“NPI”) projects for molded parts as required.

• Support Production and Engineering with tooling/technical problems

• Adhere to all ISO and OSHA regulations.

• Special projects and all other duties as assigned.

Skills & Experience

Education, Skills & Experience:

• Excellent leadership and project management skills are required.

• Bachelor’s degree in Manufacturing Engineering (or Mechanical) is preferred.

• 5+ years of Tooling Engineering experience or related experience is required.

• Technical understanding of all Tool Room equipment and processes.

• Knowledge of high performance plastics and their properties is preferred.

• Strong knowledge of the various processing conditions in molding such as flow, temp, speeds, pressures, viscosity, density, etc.

• Strong technical aptitude, experience with Solid Works is preferred.

• Excellent problem solving and troubleshooting skills.

• Working knowledge of manufacturing software is preferred, Visual Manufacturing a plus.

• Adaptability to adjust to rapidly changing work environments and operational situations.

• Adhere to all AS9100 requirements.