Tool Room Machinist (2nd shift)

Job Description

Tool Room Machinist (2nd Shift)

Position Summary:

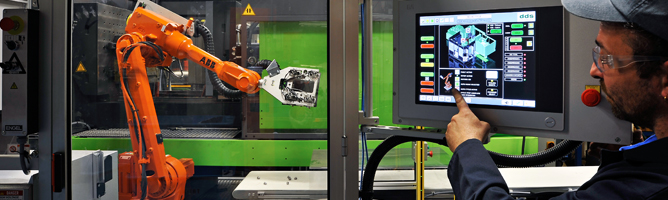

This position is responsible for operating all CNC and manual equipment located in the Tool Room. The work assignments may include reading and understanding blueprints, tool making, touch off of tools, layout, set up, minor machine maintenance and machine operation. The position requires direct communication with engineers and production in order to resolve issues. It also requires the ability to work independently, adhere to strict safety guidelines, maintain a clean work area and keep all equipment in good, working condition.

Skills & Experience

Responsibilities & Accountabilities:

- Perform all required machine operations to construct, alter or repair injection molds, jigs, fixtures, dies and gauges.

- Proficiency in flat and form grinding, vertical milling, lathe, die sinking EDM, Wire EDM and CNC milling.

- Read and interpret blueprints and drawings.

- Support and adhere to ISO 9002 as described by the Tri-Mack Plastics Quality Manual and supporting documentation.

- Demonstrate a personal commitment to quality, health and safety. Adhere to all state and federal laws concerning hazardous materials.

- Physical ability to stand, bend, sit and lift up to 40 pounds for 8 to 12 hours per day.

- All other assigned duties.

Education, Skills & Experience:

- High School diploma or general education degree (GED) and minimum of two to four years related experience.

- Prior experience on milling machines (CNC and manual) is required.

- Prior experience on lathes and grinders is preferred.

- Experience with general QC equipment, including micrometers, calipers,etc.

- General math knowledge and ability to calculate and solve certain geometric problems.

- Basic computer skills.

- Ability to train, support and interact with coworkers.

About Tri-Mack:

Tri-Mack Plastics is an engineering driven custom manufacturer for the aerospace, chemical, and medical industries. We inject mold engineering grade resins and machine the molded parts to tight tolerances using CNC milling and CNC turning centers. We are located in Bristol, Rhode Island and have been in business since 1974.

Tri-Mack is an Equal Employment Opportunity (EEO) employer. It is the policy of Tri-Mack to provide equal opportunities to all qualified applicants withour regard to race, color, religion, sex, seual orientation, gender identity, national origin, age, proected veteran or disabled status, or genetic informaiton.

*Tri-Mack Plastics is a drug-free work environment. Pre-employment drug screening and background checks are required.