Senior Manufacturing Quality Engineer

Job Description

Senior Manufacturing Quality Engineer

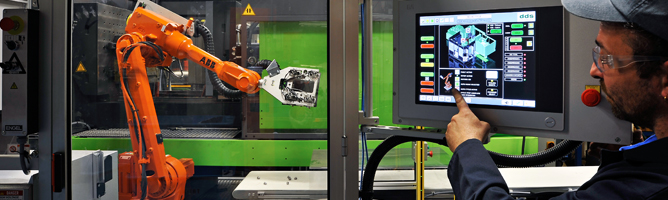

Position Summary: The Senior Manufacturing Quality Engineer (SMQE) is responsible for the quality systems and documentation for new and existing products to ensure that 100% conforming product is shipped to customers. The SMQE will work very closely with engineering and manufacturing on design and process reviews to make sure that products can be consistently manufactured to meet all quality requirements. This position will also support customer related quality issues from NPI through completion. This includes fielding customer related complaints, establishing corrective actions and implementing improvements to our quality system.

Responsibilities & Accountabilities:

• Strong technical involvement in the NPI process, including thorough review of new prints for GD&T, tolerancing and how they relate to manufacturability and inspection.

• Support resolution of internal quality and yield issues by working closely with manufacturing and engineering to implement robust solutions.

• Drive measurement systems and technology improvements. • Provide inspection guidance to others, acting as an inspection expert.

• Establish and maintain process capability studies. • Customer contact with regard to NPI and quality issues.

• Investigate and correct customer issues and complaints relating to quality. This requires using all tools available (i.e. root-cause analysis) to ensure a satisfactory resolution both internally and externally.

• Determine the process for containment escapes and develop short and long term corrective actions.

• Analyze trends in complaints, escapes and near misses and implement improvements in our quality system.

• Participate in the daily MRB meetings and resolve significant issues.

• Revise, review and update ISO work instructions as needed.

• Integrate process control data analysis into final inspection plans.

• Support internal and external audits as required.

• Interact with vendors to ensure quality of all purchased parts.

• Adhere to all AS9100 requirements.

• All other duties as assigned.

Skills & Experience

Education, Skills & Experience:

• BS in Engineering is required.

• 7- 10 years working in Manufacturing/Quality Engineering or Quality Control management is required.

• Demonstrated knowledge and experience working directly with customers and addressing customer complaints is required.

• Strong command of GD&T.

• Lean/Six Sigma experience (Green Belt/Black Belt) with a proven track record of business performance improvement is preferred.

• Experience in maintaining ISO Compliance and Certification is required. • Previous experience in plastic injection molding or composites environment is preferred.

• Experience in Aerospace manufacturing and government contracts is preferred.

• Use of computers and Microsoft Word, Excel and Outlook.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening and background checks are required.