Project Engineer

Job Description

Position Summary: The Project Engineer provides support to Engineering in the New Product Introduction (NPI) design initiatives and/or Process Improvement projects (IMPs). This position utilizes Visual Manufacturing and Solidworks to design, develop and revise new and existing products. This position manages and assists with all engineering projects as requested.

Responsibilities & Accountabilities:

• Prepare and maintain Engineering masters, including any IPQC detail as needed for any new parts under the NPI umbrella as well as update masters when process improvements are involved.

• Participate in several new and existing injection molding or composite engineering projects simultaneously from start to finish under the guidance of other Project Engineers. Work with Production to establish timelines to deliver projects on time.

• Assist in the design of new injection molding tools as well as debug existing tools.

• Ultizes Design of Experiments (DOE), Quality Function Deployment (QFD), Process Mapping and Statistics to support existing processes and NPI.

• Participate as a team member with Marketing, Quality Control, Production, Customers and Vendors to accomplish on time and on budget projects to completion.

• Work closely with Quality Control to ensure all parts meet specified drawing requirements.

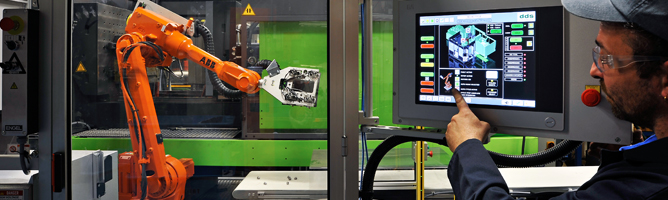

• Assist with projects to improve productivity and reduce rejection rates through the implementation of process control, automation, or modifcations.

• Adhere to all AS9100 requirements. • All other duties as assigned.

Skills & Experience

Education, Skills & Experience:

• Bachelor’s degree in Plastics, Composites, Industrial or Manufacturing Engineering is required.

• Strong technical aptitude, experience with Solid Works is required.

• Demonstrated written and oral communication skills

• Requires good blueprint reading skills, GD&T skills are preferred.

• Ability to analyze and prioritize information as well as understand the demands of engineers, sales reps, and production operators.

• Working knowledge of machining methods, procedures, and cost-reduction techniques is helpful.

• Must be able to get along with others as well as work independently.

• Use of computers and Microsoft Word, Excel, Outlook and Power Point.

About Tri-Mack:Tri-Mack Plastics is an engineering driven custom manufacturer for the aerospace, chemical, and medical industries. We inject mold engineering grade resins and machine the molded parts to tight tolerances using CNC milling and CNC turning centers. We are located in Bristol, Rhode Island and have been in business since 1971.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening and background checks are required.