Injection Molding Operator (1st and 2nd shift)

Job Description

Injection Molding Operator

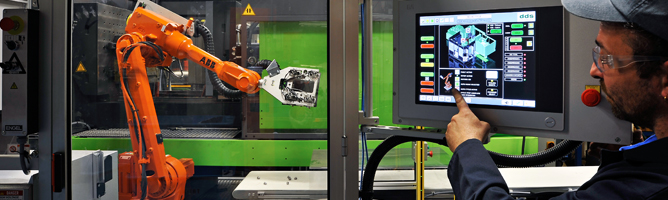

Position Summary: This position is responsible for running plastic injection molding machines, de-gate and de-bur parts while keeping the machine on-cycle. This position must measure parts with micrometers, calipers, height gages, optical comparators and documenting results.

Responsibilities & Accountabilities:

• Keep molding machines on cycle.

• Fill material hopper as needed.

• De-bur, de-flash and edge break plastic parts.

• Section and prepare sample parts.

• Measure parts and record results.

• Visually inspect all parts for molding flaws.

• Assemble parts using mechanical fasteners such as screws, bolts, and rivets.

• Maintain safe operations by adhering to safety procedures and regulations.

Skills & Experience

Education, Skills & Experience:

• Experience using razor knives, sanders and other de-gating equipment.

• Ability to speak and read in English

• Ability to read and interpret blueprints and use measuring equipment.

• Strong interpersonal skills.

• Strong organizational skills.

• Ability to work in a team environment.

About Tri-Mack: Tri-Mack Plastics is an engineering driven custom manufacturer for the aerospace, chemical, and medical industries. We inject mold engineering grade resins and machine the molded parts to tight tolerances using CNC milling and CNC turning centers. We are located in Bristol,Rhode Island and have been in business since 1971.

*Tri-Mack Plastics provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, age, protected veteran or disabled status or genetic information. Tri-Mack is a drug-free work environment. Pre-employment drug screening and background checks are required.